Are you a manufacturing service provider looking for business growth? Then this article by Innovana3D provides a comprehensive manual for growing your manufacturing business. The article discusses the key challenges and opportunities for manufacturing business growth.

Challenge 1: Lack of Floor Space to install new machines or materials

Lack of floor space is a severe issue as it can result in business losses due to the inability to fulfill business orders. Additionally, it limits growth as new machines and systems cannot be installed. The potential solution for this issue is using lean manufacturing principles to reduce the time and space required for production. Moreover, using lean manufacturing principles can also improve the quality of the finished products. The other methods that can overcome the floor space challenge are better materials handling procedures and software dedicated to floor space optimization and management.

Challenge 2: Improper Customer Management

The manufacturing service business can be risky if most revenues come from only a limited number of customers. For example, having more than 75% of business from only 2-3 customers can be risky. In addition, the other challenge is not providing proper customer service based on the feedback. These challenges can be overcome by diversifying the business, which will reduce the risk and, in addition to this it, will also ensure revenue growth. The other method is ensuring a proper customer management system that can provide appropriate support to all the customers.

Challenge 3: Human Resource Challenges

According to a recent article published in Forbes, Labor Shortage is one of the significant issues that the U.S.A.’s manufacturing companies are facing. According to another study published by Deloitte, labor shortage in the U.S.A will result in an opportunity cost loss of 1 trillion dollars per year. To overcome this challenge, two methods can be adopted by the manufacturing service provider. First is proper training and management of human resources so that hiring and performance challenges do not affect the production process. Second is the use of advanced technologies such as robotics, automation, and artificial intelligence to reduce the requirement of human resource on repetitive tasks and improve production quality.

Opportunity 1: Adapting advanced software

The manufacturing service provides the need to use a wide range of software for design, simulation, optimization, and management. Using advanced software can significantly reduce the time required for operation and improve engineering quality. Innovana3D is a quote generation and management software that can generate quotations. Compared to the traditional method, which may take around 2-3 business days, using Innvoana3D this time can be reduced to just a few minutes. This improvement is further reflected in customer satisfaction and improves the revenue for the business.

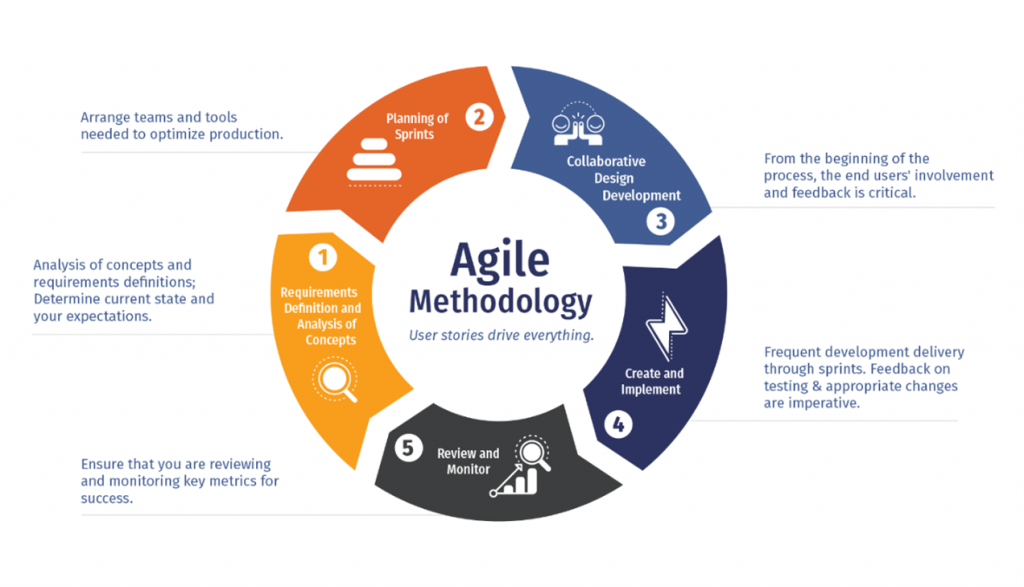

Opportunity 2: Using Agile Methodology

Agile methodology is a continuous improvement process involving all the organization’s stakeholders. With the rapid technological changes, it has been critical for the manufacturing service provided by agile. It can make the process of continuous improvement faster and ensure the decisions involve all the stakeholders.

Opportunity 3: Developing a presence online

In today’s era use of digital marketing helps customers to make BtoB decisions, and a manufacturing service provider must use digital marketing tools to develop an online presence. In addition, it also helps the company reach broader audiences and improve reach. Using digital quotes-producing software such as Innovana3D could help you convert your online audience into customers by providing them with faster quotes.